CONCRETE OVERLAY FLOORS

Providing quality concrete overlay flooring to Iowa City and Cedar Rapids.

What is a concrete overlay?

- Skim coat/broom finish concrete resurfacing – Restore and protect damaged, pitted, flaking and stained concrete back to the look of a new concrete surface.

- Concrete regrading & leveling – Repair and level concrete surfaces that have settled.

- Existing substrate redecorating and renovating – Alter the appearance of existing concrete or wood substrates through applying “thin stamped” or “thin stained” overlays, creating new textures, colors and designs.

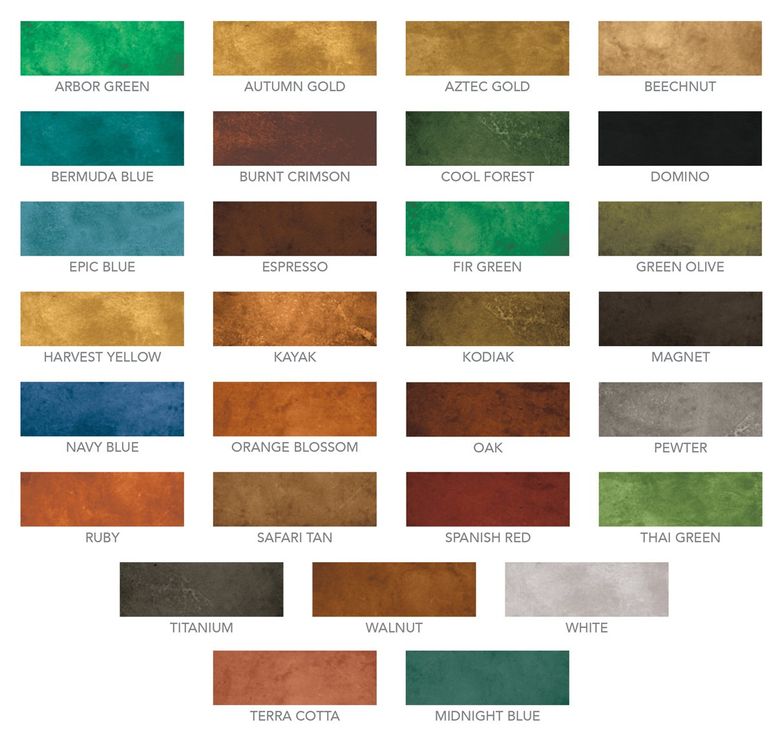

Surecrete Eco-Stain Color Chart

Surecrete Master Color Chart

-

Stamped Concrete Overlays Our stamped concrete overlays are designed for beautifying both interior and exterior concrete surfaces. When stamped, it creates a texture that can resemble a whole array of stamp designs: tile, cut stone, slate, brick, cobblestone, etc. CGI offers concrete restoration, repair, resurfacing, architectural accenting and surface protection. Our product has zero VOC’s and is designed to have excellent bond in freeze thaw climates.

Stamped Concrete Overlays -

Light Texture (Troweled Application) – Knockdown Overlay These surfaces are good for both interior and exterior concrete surfaces. The knockdown texture provides a non skid surface. Typical areas of application include pool decks, patios, walkways, and driveways for both residential and commercial projects. Our product is formulated to provide excellent bonding to new as well as existing concrete surfaces including freeze thaw climates.

Light Texture (Troweled Application) – Knockdown Overlay -

Thin Concrete Overlay This surface is great for both interior and exterior concrete surfaces. Our product delivers a multitude of textures from: trowel down, wet bubble, stencil patterns, euro-stone, bubble texture, and more. Typical areas of application include pool decks, patios, walkways, and driveways for both residential and commercial projects. Our product is formulated to provide excellent bonding to new as well as existing concrete surfaces including freeze thaw climates.

Thin Concrete Overlay -

"Broomed" Texture Overlay The "broomed" overlay is designed for leveling and retexturing both interior and exterior concrete surfaces. When broomed, it creates a texture that resembles freshly poured and broomed concrete. Typical areas include parking decks, driveways, sidewalks, parking lots or any horizontal concrete surface requiring repair of spalled areas, low spots, etc. Our product is applied with a base coat using squeegees, and then broomed. When applied properly the newly broom surface creates a slip resistant finish that we then seal to protect. This concrete overlay is suitable for heavily trafficked areas and is formulated to provide excellent bonding to new as well as existing concrete surfaces including freeze thaw climates.

"Broomed" Texture Overlay

CGI

Serving: Iowa City | Cedar Rapids | North Liberty | Surrounding Area

Local Phone: (319) 631-5459

Toll Free: (855) 88E-POXY